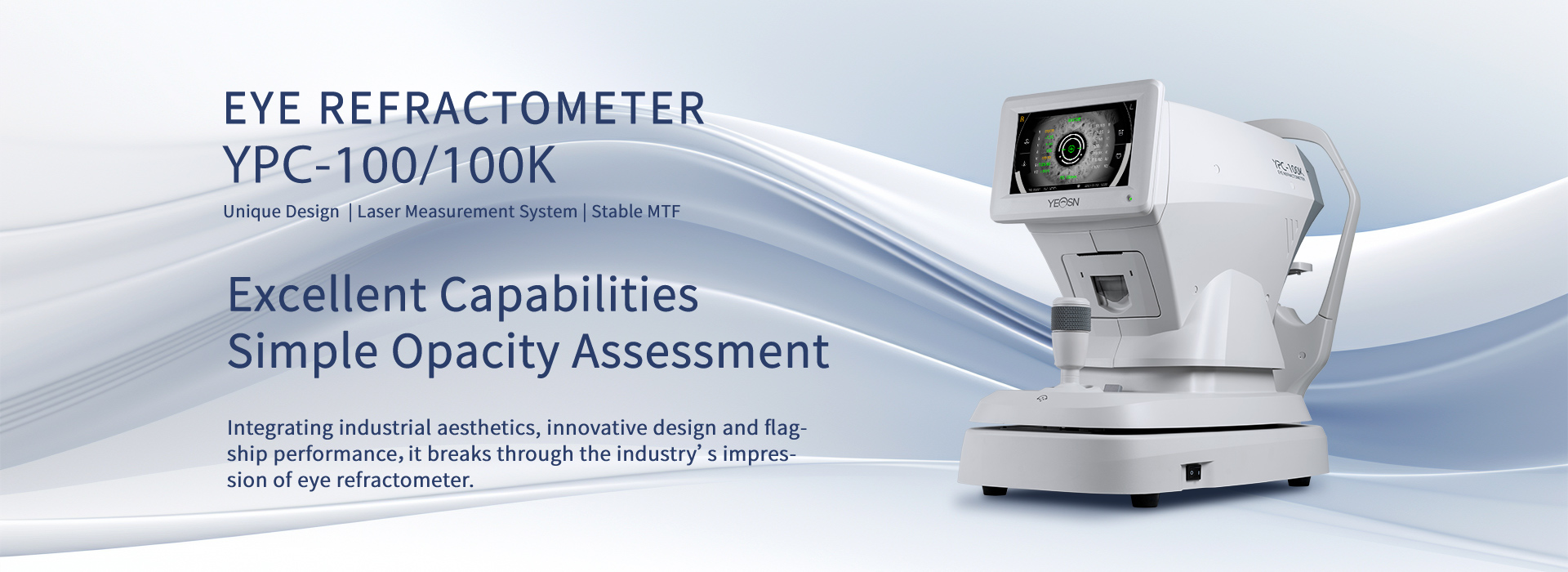

YPC-100/100K EYE REFRACTOMETER

YPC-100/100K EYE REFRACTOMETER

Using near-infrared laser provides concentrated energy and produces stable projected images

NIR Band Enhanced Sensor

Equipped with a SONY? NIR band enhanced sensor, it can provide >90% quantum efficiency within the range of 700-850nm

Real-Time Eye Position Height Indication

The direction in which the jaw support and measurement window need adjustment can be determined through a progress bar

Near-Infrared Laser Measurement Technology

Using near-infrared laser provides concentrated energy and produces stable projected images

NIR Band Enhanced Sensor

Equipped with a SONY? NIR band enhanced sensor, it can provide >90% quantum efficiency within the range of

700-850nm

Real-Time Eye Position Height Indication

The direction in which the jaw support and measurement window need adjustment can be determined through a

progress bar

WDR technology and multi-frame fusion imaging to achieve excellent image quality

The entire imaging area has outstanding resolution of over 20LP/mm

Imported two-phase hybrid stepper motor with open-loop subdivision control

7-inch fully laminated LCD screen with a resolution of 1024×600, supporting tilt adjustment from 5° to 80°

| Sphere | -30.00D ~ +25.00D(Step 0.12/0.25) |

| Cylinder | -10.00D ~ +10.00D(Step 0.12/0.25) |

| Axis angle | 0° ~ 180°(Step1°/5°) |

| Minimum pupil diameter | φ2.0mm |

| *Corneal curvature radius | 5.00mm ~ 10.00mm(Step0.01mm) |

| *Corneal refractive power | 33.75D ~ 67.50D(Step 0.12/0.25) (Corneal equivalent refractive index =1.3375) |

| *Corneal Cylinder power | -10.00D ~ +10.00D(Step 0.12/0.25) |

| *Corneal Cylinder axis | 0° ~ 180°(Step 1°/5°) |

| Pupil distance | 30mm ~ 85mm(Step 1mm) |

| Interface | USB,RS-232,LAN |

| Printer | 58mm Thermal Printer,φ50mm Paper roll |

| Packing size and weight | 280mm(W)×515mm(D)×460mm(H)/18kg |

| Power supply | 110-240V~,50-60Hz,70VA |